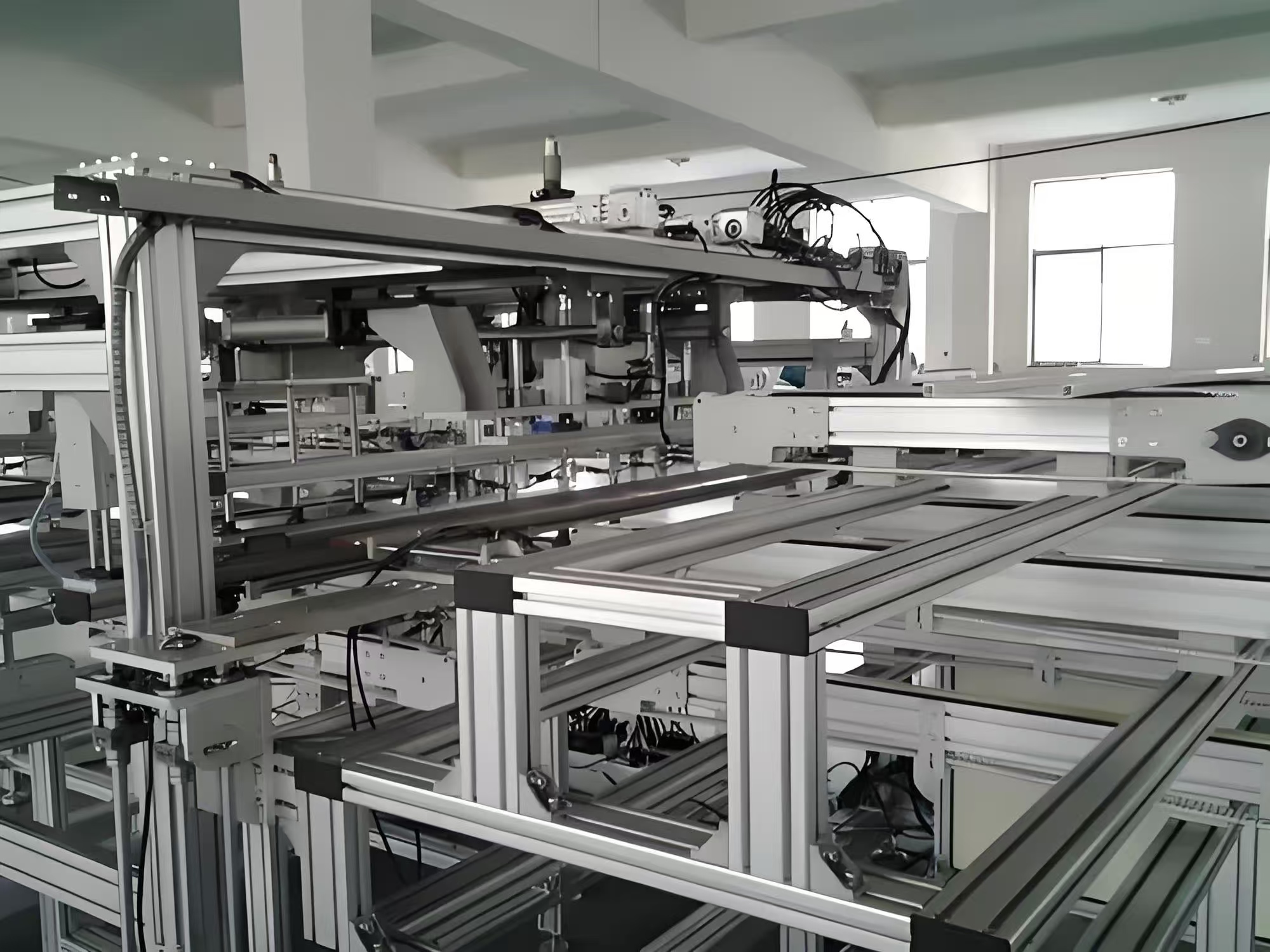

Our aluminum alloy extrusion workshop is a well - organized and efficient production facility. Spanning an area of approximately 20,000 square meters, it houses four automated aluminum alloy extrusion production lines.

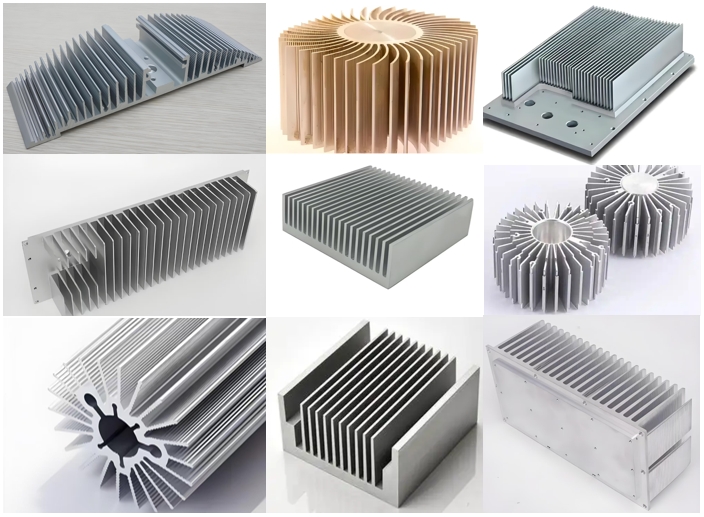

These production lines are equipped with advanced extrusion machines and automated control systems, which ensure high - precision and high - efficiency production processes. They can handle a wide range of aluminum alloy materials, producing various profiles to meet different market demands.

In the workshop, items are neatly arranged. Raw materials, semi - finished products, and finished products are clearly classified and stored in designated areas. The material flow lines are rationally planned, enabling smooth transportation of materials between different production stations. This not only improves production efficiency but also reduces the risk of material damage and confusion.

The ground of the workshop is kept clean and tidy. Regular cleaning and maintenance are carried out to ensure a dust - free and debris - free environment. This not only provides a comfortable working environment for employees but also helps to maintain the quality of products, as a clean environment minimizes the possibility of impurities contaminating the aluminum alloy during the extrusion process. Overall, our aluminum alloy extrusion workshop combines advanced production technology with scientific management, guaranteeing high - quality production and efficient operation.