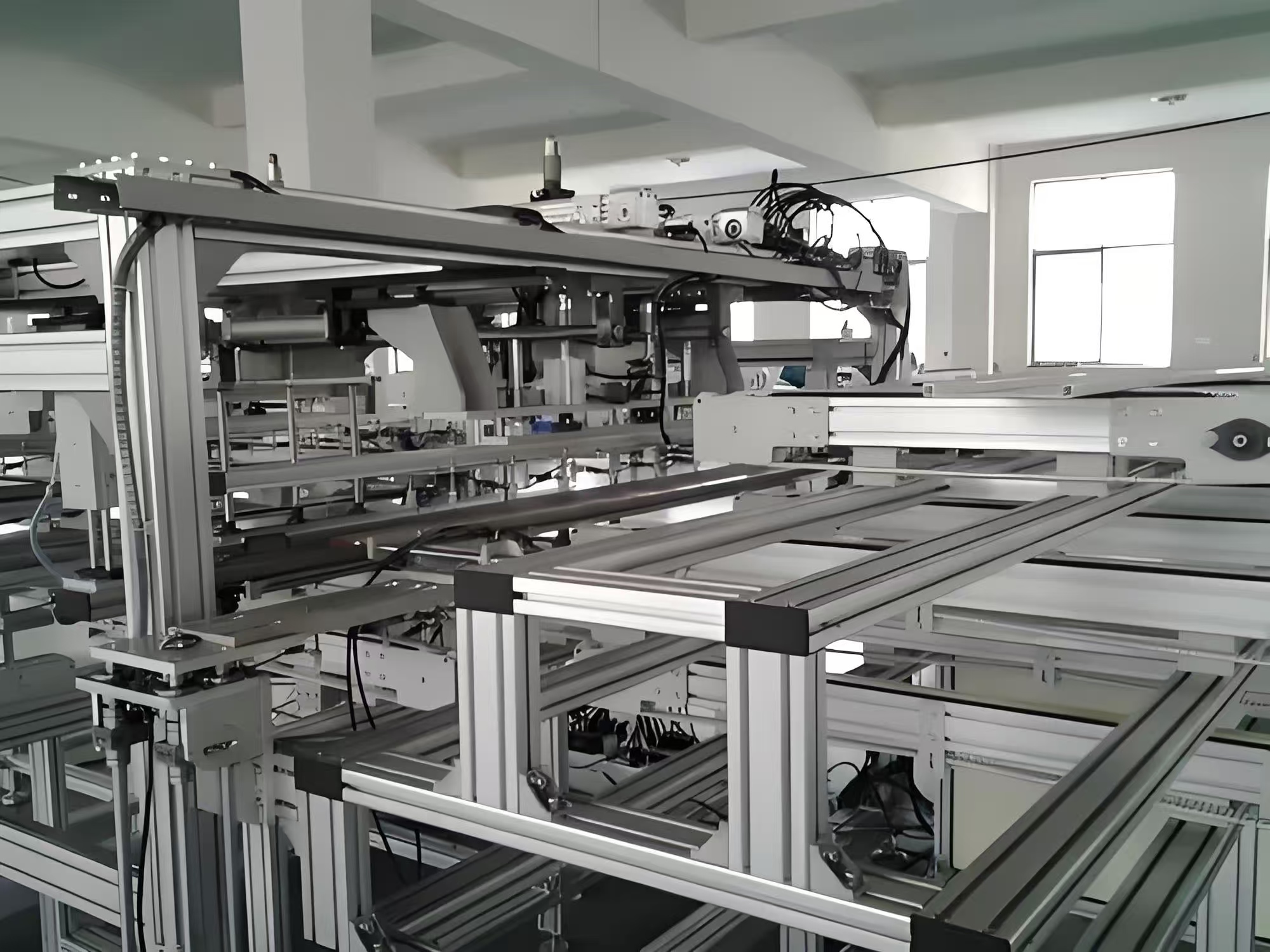

The aluminum alloy profile wood - grain transfer printing production line is a highly specialized production setup dedicated to endowing aluminum alloy profiles with a realistic wood - grain appearance.

1. Key Components and Processes

- Pretreatment: Before the transfer - printing process, the aluminum alloy profiles need to go through a meticulous pretreatment. This includes degreasing to remove any grease, oil, or contaminants on the surface, followed by a series of cleaning steps such as alkaline washing and acid pickling. These procedures ensure that the surface of the profiles is clean and suitable for subsequent processes, enhancing the adhesion of the transfer - printing film.

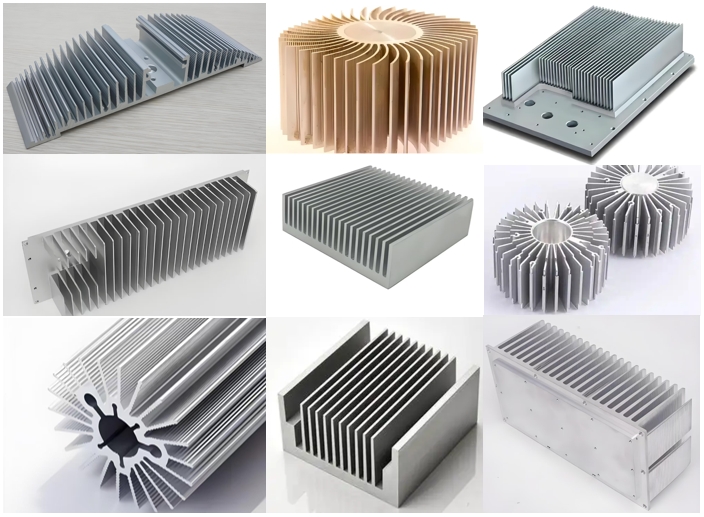

- Base Coating Application: A base coat is applied to the pretreated aluminum alloy profiles. This coat not only serves as a primer but also provides a uniform color background for the wood - grain pattern. The base coat is usually cured in an oven at a specific temperature to ensure its hardness and durability.

- Wood - Grain Transfer Printing: The core process of the production line is wood - grain transfer printing. A special transfer - printing film with a high - definition wood - grain pattern is placed in close contact with the base - coated aluminum alloy profile. Through a combination of heat and pressure, the wood - grain pattern on the film is transferred onto the surface of the profile. High - temperature and high - pressure equipment, such as a hot - press machine, is used to ensure that the pattern adheres firmly and accurately.

- Top Coating: After the transfer - printing process, a top - coat is applied to protect the transferred wood - grain pattern. The top - coat provides additional resistance to scratches, abrasion, and environmental factors. It also gives the profile a smooth and shiny finish, further enhancing its aesthetic appeal. The top - coat is then cured to complete the production process.

2. Advantages

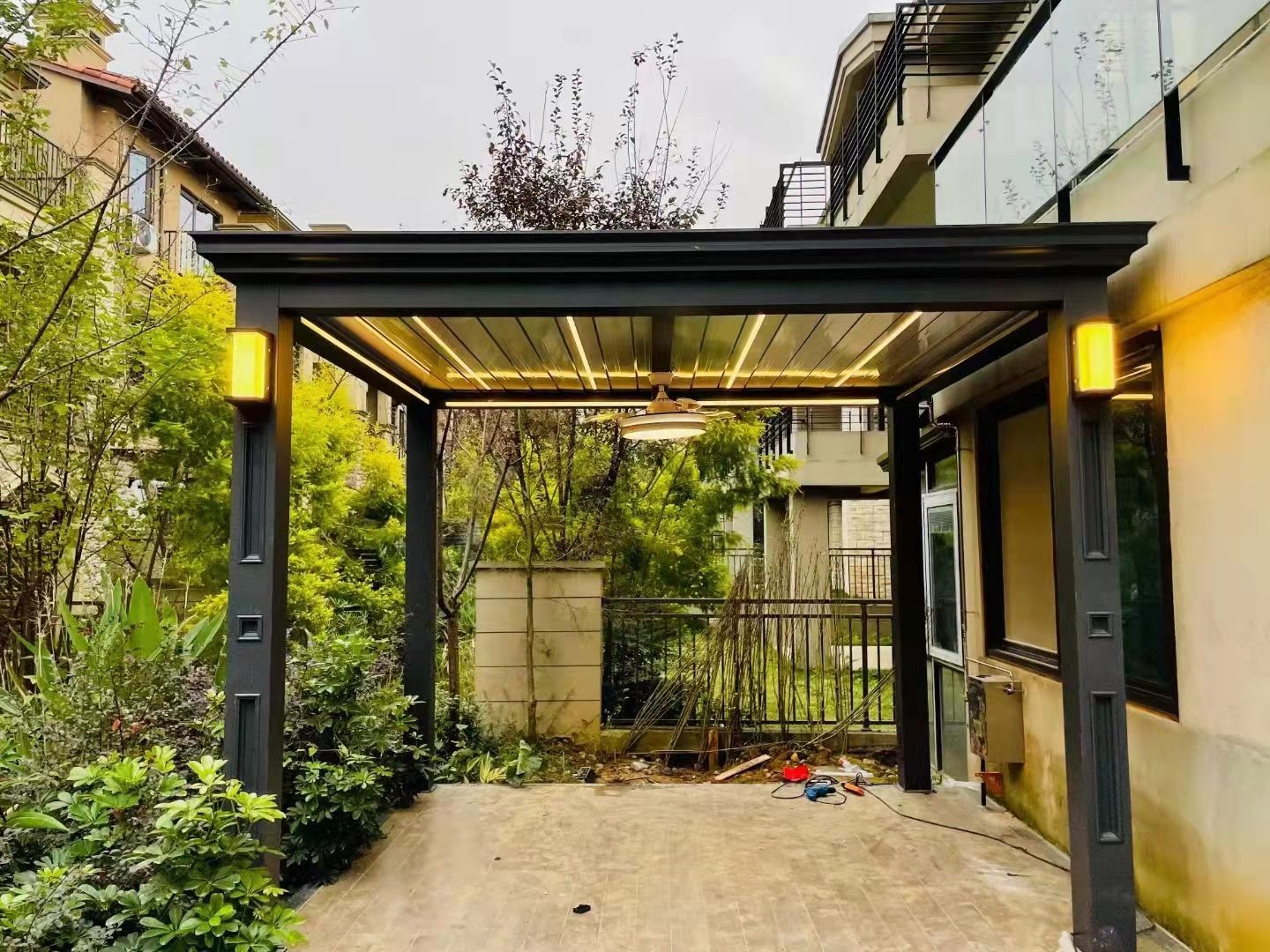

- Aesthetic Appeal: It enables aluminum alloy profiles to mimic the natural beauty of real wood, providing a warm and elegant look that can meet the design requirements of high - end interior and exterior decoration projects.

- Durability: The combined coatings and the transfer - printed pattern offer excellent resistance to corrosion, weathering, and wear, making the aluminum alloy profiles more durable than natural wood in various harsh environments.

- Versatility: The production line can produce a wide variety of wood - grain patterns, allowing manufacturers to meet different customer preferences and design trends.

- Environmental Friendliness: Compared to using real wood, which may contribute to deforestation, aluminum alloy profiles with wood - grain transfer printing are a more sustainable choice. Aluminum is a recyclable material, and the production process has a relatively low environmental impact.

This production line is widely used in the construction industry for window frames, door frames, curtain walls, as well as in the furniture manufacturing and interior decoration industries, providing cost - effective and aesthetically pleasing solutions.