Applications of Aluminum Alloy Industrial Automation Profiles in Automation Equipment

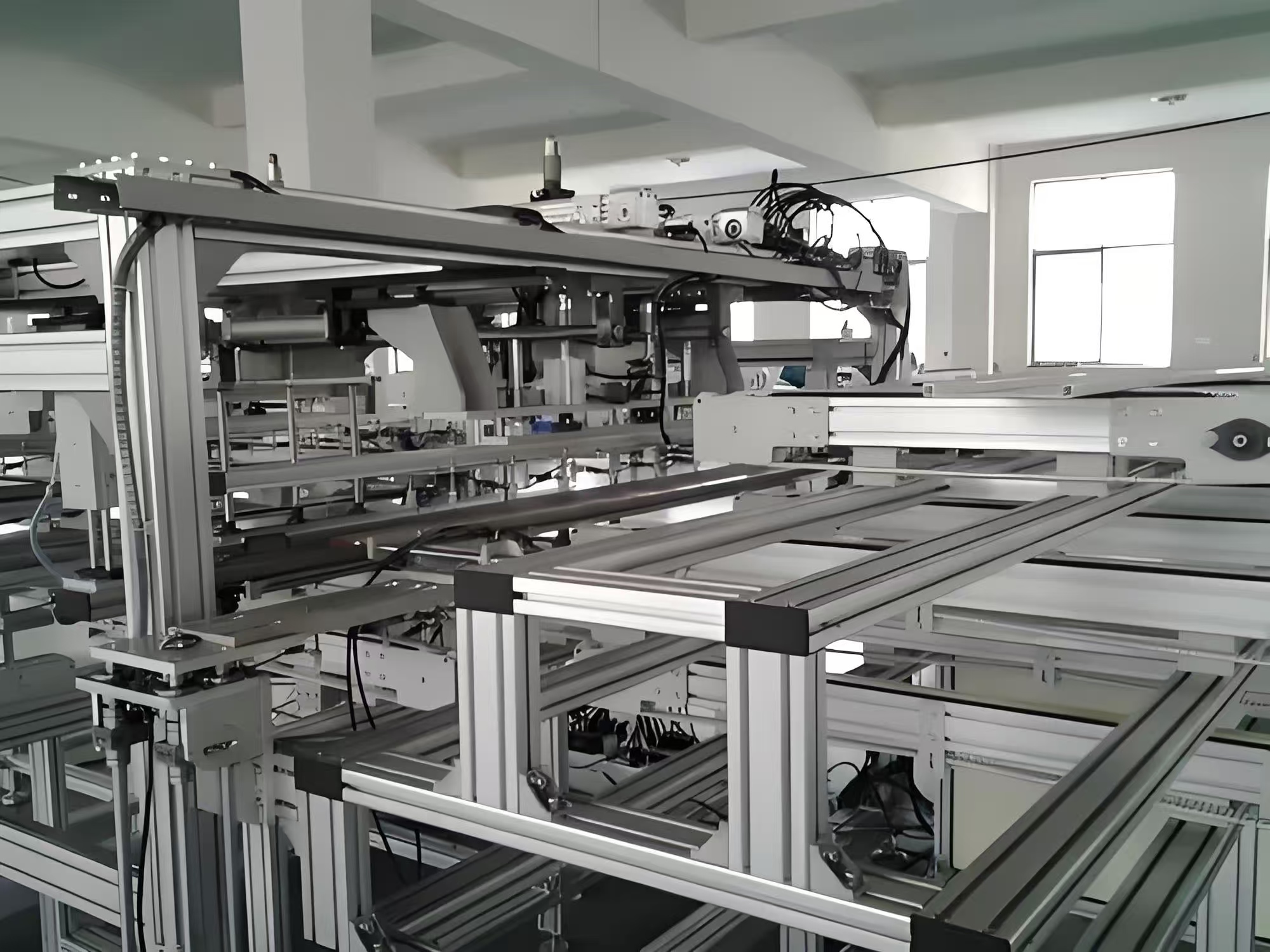

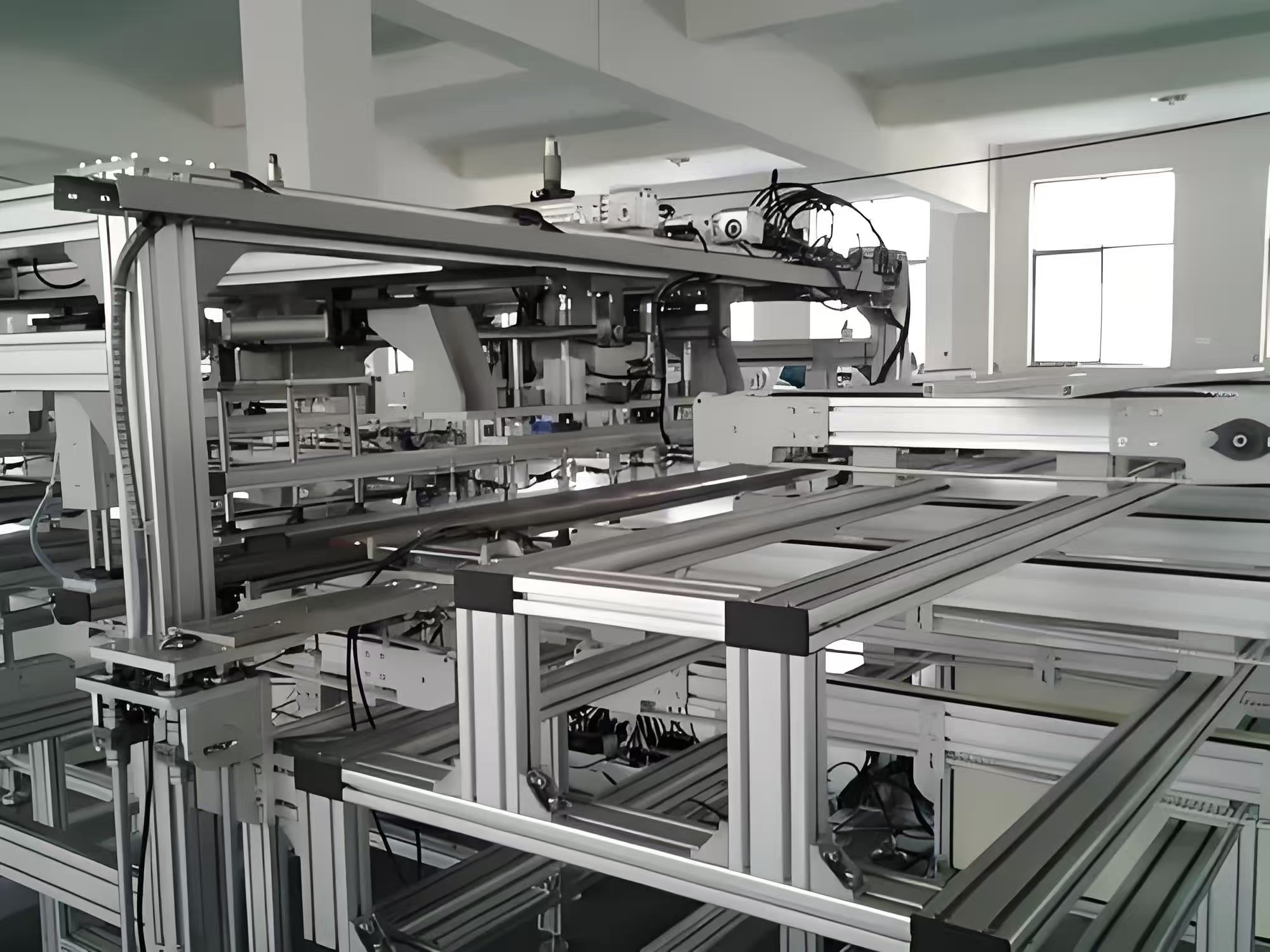

Aluminum alloy industrial automation profiles have found extensive applications in modern automation equipment, especially in the frameworks of assembly lines and automated inspection equipment, due to their unique properties.

1. Assembly Lines

Structural Support In assembly lines, the smooth operation of material transportation and product assembly depends on a stable framework. Aluminum alloy profiles, with high strength - to - weight ratio, are ideal for this purpose. They can bear the weight of various components such as conveyor belts, motors, and workbenches while remaining lightweight. This not only simplifies the installation process but also reduces the energy consumption of the overall equipment during operation. For example, in an automotive assembly line, the large - scale framework made of aluminum alloy profiles can support the heavy - duty conveyor systems that transport car bodies, ensuring precise movement and positioning during the assembly process.

Modularity and Flexibility Assembly lines often need to be reconfigured according to different production requirements. Aluminum alloy industrial automation profiles offer excellent modularity. They come in a variety of standard sizes and shapes, and can be easily connected using bolts, nuts, and special connectors. This allows for quick disassembly, rearrangement, and expansion of the assembly line framework. A 3C product assembly line may need to be adjusted frequently to accommodate the production of different models. The modular nature of aluminum alloy profiles enables engineers to modify the layout of the line in a short time, improving production efficiency and adaptability.

2.Automated Inspection Equipment

Stability for Precision Detection Automated inspection equipment requires a highly stable framework to ensure accurate detection results. Aluminum alloy profiles, with good dimensional stability and resistance to deformation, can meet this requirement. In optical inspection equipment, even a slight vibration or deformation of the framework can cause errors in image acquisition and analysis. The rigidity of aluminum alloy profiles effectively reduces such risks, enabling the inspection equipment to maintain high - precision operation. For instance, in a semiconductor wafer inspection machine, the aluminum alloy profile - based framework provides a stable platform for the high - magnification optical lenses and sensors, guaranteeing the accurate detection of tiny defects on the wafer surface.

Corrosion Resistance in Harsh Environments Some automated inspection equipment may be used in environments with moisture, chemicals, or dust. Aluminum alloy profiles have natural corrosion - resistance properties. This makes them suitable for applications in food inspection lines where there may be moisture and cleaning agents, or in industrial inspection equipment in chemical plants. The corrosion - resistance of aluminum alloy profiles ensures the long - term reliability and durability of the inspection equipment framework, reducing maintenance costs and downtime.

In conclusion, aluminum alloy industrial automation profiles play a crucial role in the frameworks of assembly lines and automated inspection equipment. Their properties of high strength - to - weight ratio, modularity, stability, and corrosion resistance make them an indispensable material in modern automation equipment manufacturing, contributing to the improvement of production efficiency and product quality.