In everyday 's morning meeting, we will focus on several key aspects to ensure our daily operations run smoothly and efficiently.

1. Production Schedule

- We have a tight production schedule these days . The target is to meet our customer's deadline . Each production line should strictly follow the planned output and time nodes to avoid any delay.

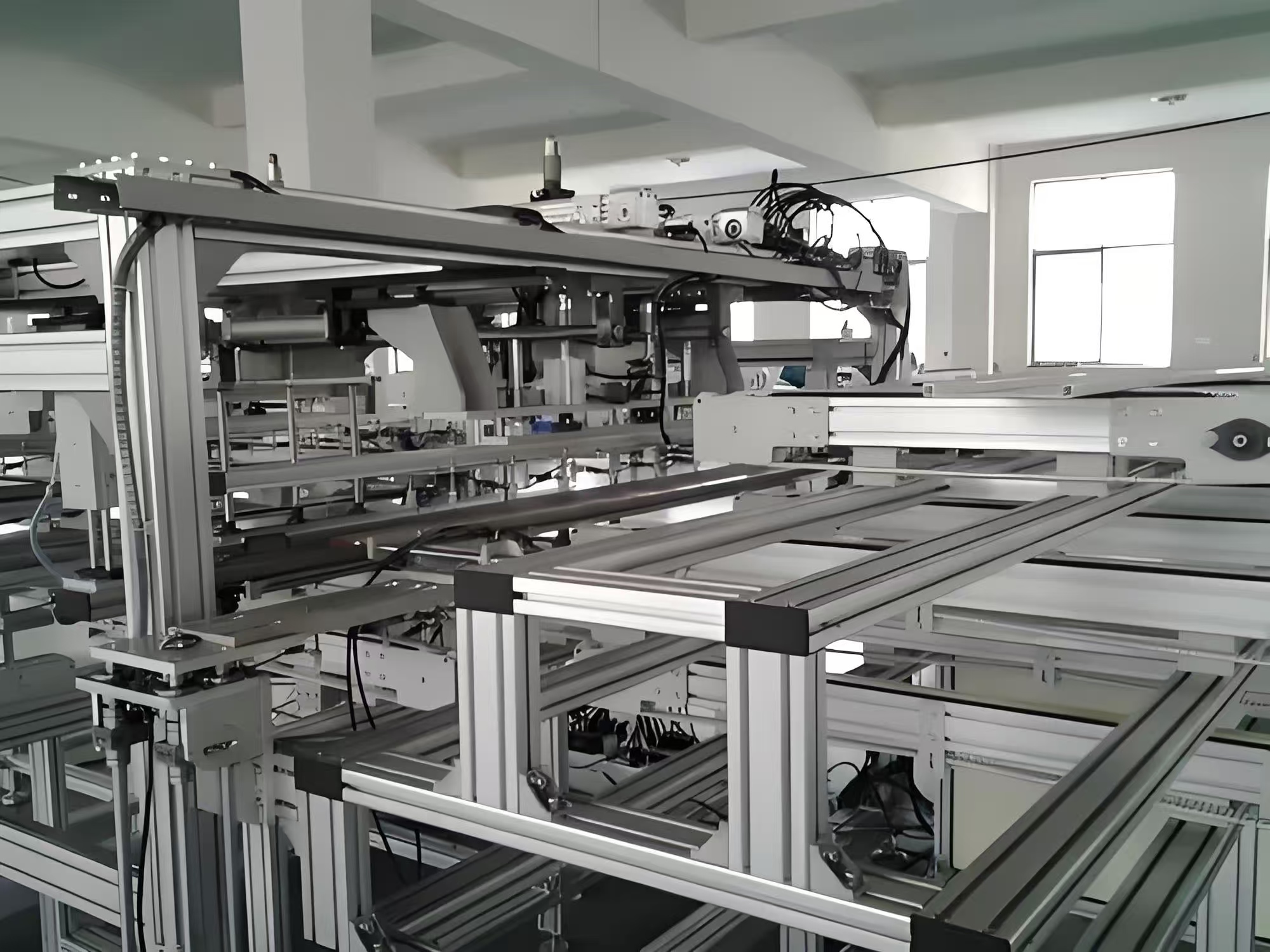

- For the extrusion process, the production rate should be maintained at [X] meters per minute, and the defect rate should be controlled within 3%.

2. Quality Control

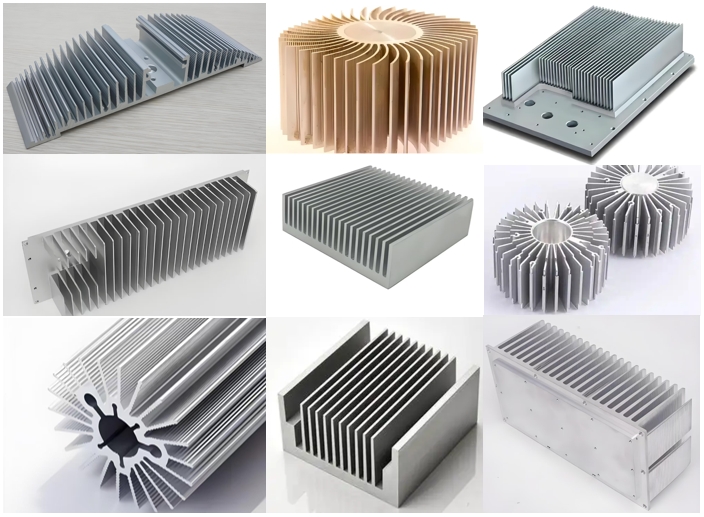

- Quality is our top priority. During the production process, every worker must conduct self - inspections at regular intervals. For the aluminum alloy profiles, pay close attention to surface quality, dimensional accuracy, and mechanical properties.

- Random sampling inspections will be carried out by the quality control team. Any unqualified products must be immediately identified, marked, and isolated to prevent them from entering the next production process.

3. Safety Regulations

- Safety in the workshop is non - negotiable. Always wear personal protective equipment, including safety helmets, safety shoes, and protective gloves.

- Before operating any equipment, make sure to conduct a pre - operation inspection to ensure its normal operation. In case of any equipment failure or safety hazards, report to the maintenance department immediately.

- Do not operate equipment beyond its rated capacity, and follow the correct operating procedures strictly.

4. 5S Management

- Keep the workshop clean and tidy. Sort out unnecessary items regularly to create a more spacious and organized working environment.

- Set in order all tools and materials, and mark their storage locations clearly for easy access.

- Maintain the cleanliness of work areas, equipment, and passageways. Everyone should develop the habit of cleaning up after themselves.

- Standardize all work processes to ensure consistency and efficiency.

- Sustain the implementation of the above 4S requirements to form a long - term good working habit.

Let's work together to achieve better production results while ensuring quality, safety, and a pleasant working environment.