Here is a detailed introduction to the aluminum alloy comb - shaped heat sinks profile :

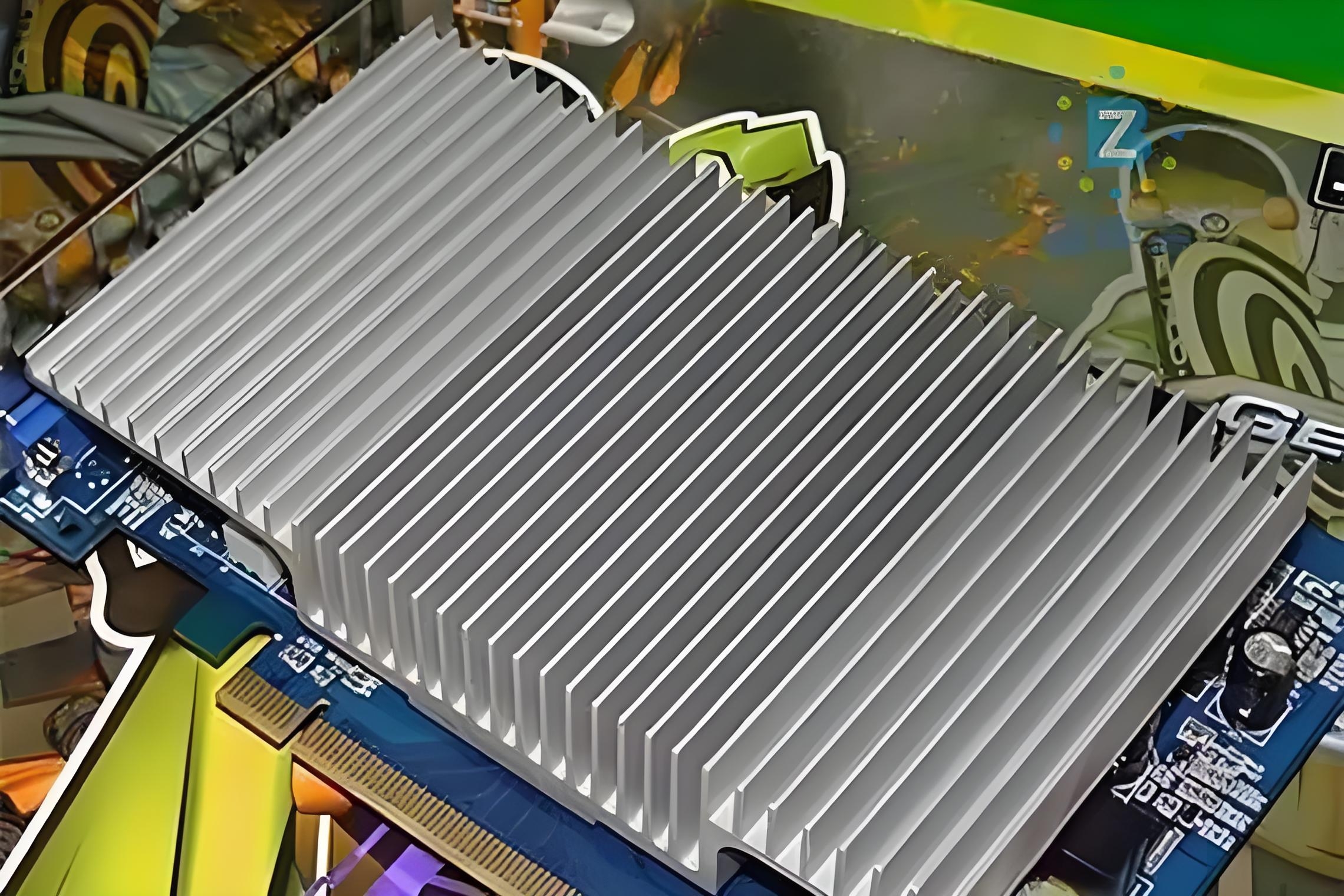

Comb - shaped heat sinks profile is widely used in electronic devices like computers, laptops, and servers. The comb - shaped design can effectively dissipate the heat generated by high - power components such as CPUs and GPUs, ensuring the stable operation of the devices.

Heat Dissipation Effect:

- The comb - shaped heat sinks design of the heat sink profile significantly increases the surface area in contact with the air. This allows for more efficient heat transfer through convection. The high thermal conductivity of aluminum alloy enables rapid conduction of heat from the heat source to the surface of the profile. As a result, the heat can be quickly dissipated into the surrounding environment, effectively reducing the temperature of the heat - generating components .

Customized Structural :

- We can provide customized services according to different application requirements. For example, in some high - power electronic devices, the profile can be designed with a larger number of teeth and a thicker structure to increase the heat - dissipation area. In other cases, where space is limited, a more compact comb - shaped structure can be designed to meet the installation requirements while still ensuring good heat - dissipation performance.

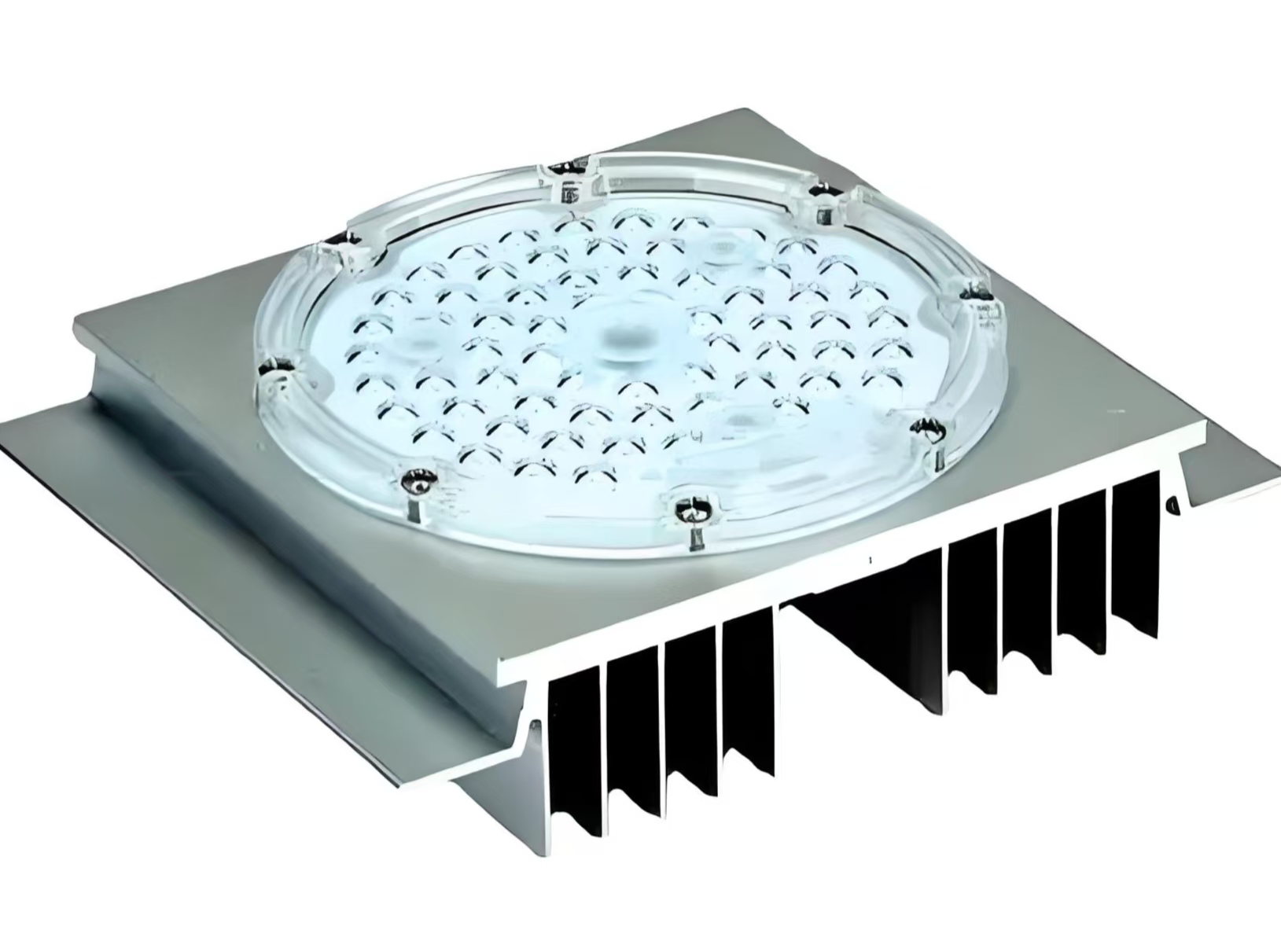

Made from aluminum alloy, these comb - shaped heat sinks benefit from the material's excellent thermal conductivity. Aluminum can quickly absorb the heat generated by the LED chips and transfer it away. The comb - shaped design is characterized by a series of closely - spaced fins that resemble the teeth of a comb. This unique structure offers a significantly increased surface area for heat dissipation.

When installed in an LED lighting fixture, the comb - shaped heat sink is typically placed in direct contact with the LED module. The base of the heat sink makes firm contact with the heat - generating components of the LED, ensuring efficient heat transfer from the source.

After the extrusion of aluminum alloy radiator profiles, we offer comprehensive CNC machining and packaging services as part of our one - stop solution.

CNC Machining

- Precision Milling: Our state - of - the - art CNC milling machines can create complex shapes and precise dimensions on the extruded profiles. This includes milling flat surfaces to ensure a perfect fit with heat - generating components, and creating grooves or channels for better heat transfer or for the installation of additional accessories.

- Drilling and Tapping: We perform accurate drilling and tapping operations to meet various connection requirements. Whether it's for mounting the radiator on a PCB in an electronic device or attaching it to a mechanical frame, the holes and threads are made with high precision to guarantee a secure connection.

- Surface Finishing: Through CNC - controlled grinding and polishing processes, we can achieve different surface finishes.

Packaging

- Protective Packaging: We use high - quality protective materials to ensure that the machined aluminum alloy radiator profiles are well - protected during transportation and storage. Bubble wrap, foam inserts, and cardboard boxes are carefully selected to prevent scratches, dents, and other physical damages.

With our one - stop service, you don't have to worry about coordinating multiple suppliers for different production stages. We take care of everything from the initial extrusion to the final packaging, saving you time, effort, and cost. Our team of experts is committed to delivering high - quality products with efficient turnaround times, ensuring your satisfaction at every step of the process.

Our factory locates in Linqu county,Shandong Province china

Of course, we can take you to visit our factory and provide a detailed introduction. We can also take you to visit us.

Yes, we can customize the service according to your requirements. We also have a professional product development department